Product Description:

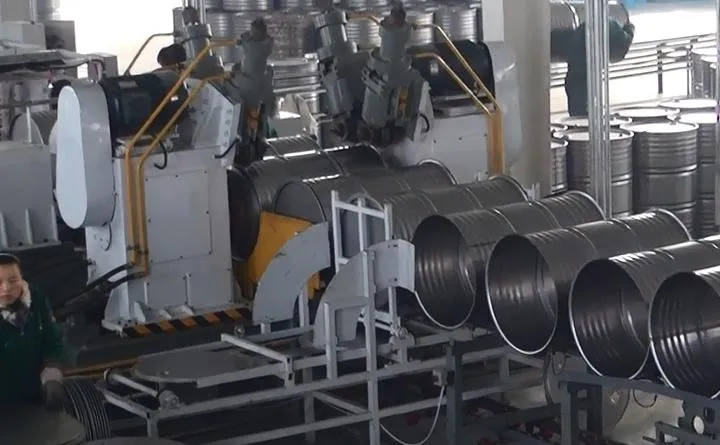

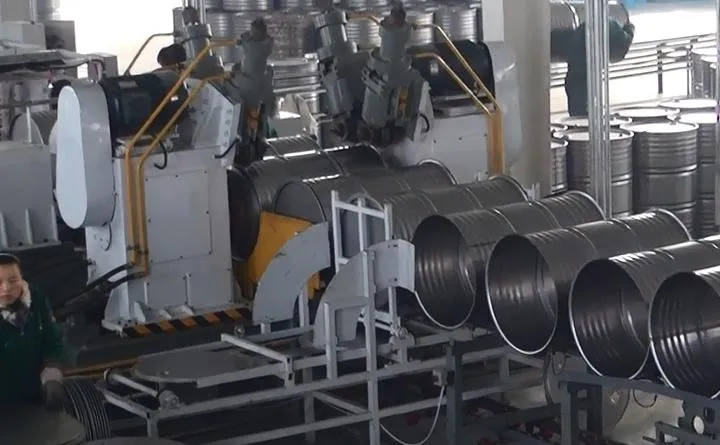

The Steel Drum Welding Production Line is a cutting-edge manufacturing solution designed to meet the demands of various industries such as manufacturing plants, construction works, energy & mining, and more. With a robust production capacity of cutting 15 times per minute, this welding machine cart offers high efficiency and productivity for your operations.

One of the key features of this welding machine steel production line is its automatic control system, which ensures seamless operation and precise welding processes. The integration of famous brand PLC technology further enhances the performance and reliability of the equipment, making it a standout choice for industrial applications.

At the core of the Steel Drum Welding Production Line lies the innovative 7 layers of circle rolling technology, which enables the machine to deliver consistent and high-quality welds. This advanced technology sets this welding machine apart from traditional models, making it a cutting-edge solution for modern manufacturing needs.

Whether you are looking to streamline your production processes, increase output, or improve the quality of your welded products, this welding machine is designed to meet your requirements. Its versatility and adaptability make it suitable for a wide range of applications across different industries, making it a valuable addition to any manufacturing facility.

In conclusion, the Steel Drum Welding Production Line is a top-of-the-line solution that combines cutting-edge technology, high production capacity, and automatic control for efficient and reliable welding operations. With its famous brand PLC, 7 layers of circle rolling technology, and suitability for various industries, this welding machine is a must-have for businesses looking to optimize their manufacturing processes and achieve superior welding results.

Features:

-

Product Name: Steel Drum Welding Production Line

-

Key Selling Points: Famous brand PLC

-

Voltage: 380v

-

Core Technology: 7 layers of circle rolling technology

-

Production Level:

-

Cutting precision Length: tolerance 0.5mm

-

Diagonal: tolerance 1mm

-

Specification: 1500 KG

Technical Parameters:

|

Welding Way

|

Seam Welding

|

|

Painting Method

|

High-pressure painting without air, fuel heating

|

|

Key Selling Points

|

Famous brand PLC

|

|

Total Weight of Equipment

|

About 55 ton

|

|

Customization

|

Available

|

|

Cooling Way

|

Water Cooling

|

|

Production Level

|

Cutting precision Length: tolerance 0.5mm; diagonal: tolerance 1mm

|

|

Applicable Industries

|

Manufacturing Plant, Construction works, Energy & Mining, Other

|

|

Total Power of Equipment

|

48KW

|

|

HS Code

|

8515219000

|

Applications:

The Steel Drum Welding Production Line is suitable for a wide range of product application occasions and scenarios. It is ideal for industrial settings where steel drum manufacturing is required, such as factories, workshops, and production facilities. This product is perfect for businesses looking to enhance their welding processes and improve efficiency.

With a minimum order quantity of 1 and a price range of $10,000 to $80,000, the Steel Drum Welding Production Line offers excellent value for money. Customers can choose from a variety of payment terms including L/C, D/A, D/P, and T/T, making it convenient for procurement.

Trintfar's production line has a supply ability of 50 per year and a delivery time of 45 to 75 days. The packaging details include wooden brackets/wooden cases for secure transportation.

Equipped with seam welding technology and high-pressure painting without air, fuel heating, this welding production line ensures precise and durable welds. The total power of equipment is 48KW, and the total weight is about 55 tons, making it robust and capable of handling heavy-duty operations.

The Steel Drum Welding Production Line has a production capacity of cutting 15 times per minute, making it suitable for high-volume manufacturing environments. Whether it's for automotive, construction, or other industries, this production line is a reliable choice for efficient and cost-effective welding processes.

Support and Services:

The Product Technical Support and Services for the Steel Drum Welding Production Line include:

- Installation assistance for setting up the welding production line

- Training sessions for operators and maintenance personnel

- Troubleshooting guidance for identifying and resolving issues

- Regular maintenance and service checks to ensure optimal performance

- Access to technical documentation and resources for reference

Packing and Shipping:

Product Packaging:

The Steel Drum Welding Production Line is carefully packaged in a sturdy wooden crate to ensure safe transportation. The components are securely wrapped and padded to prevent any damage during shipping.

Shipping Information:

Shipping Method: Freight

Shipping Dimensions: 120" x 48" x 60"

Shipping Weight: 2000 lbs

Shipping Origin: Factory location

Shipping Destination: Customer address

FAQ:

Q: What is the brand name of the Steel Drum Welding Production Line?

A: The brand name is Trintfar.

Q: What is the model number of the Steel Drum Welding Production Line?

A: The model number is FMT-80.

Q: Where is the Steel Drum Welding Production Line manufactured?

A: The Steel Drum Welding Production Line is manufactured in China.

Q: What are the accepted payment terms for purchasing the Steel Drum Welding Production Line?

A: The accepted payment terms are L/C, D/A, D/P, and T/T.

Q: What is the minimum order quantity for the Steel Drum Welding Production Line?

A: The minimum order quantity is 1.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!